1. Why choose CNC laser cutting machine?

High accuracy and consistency

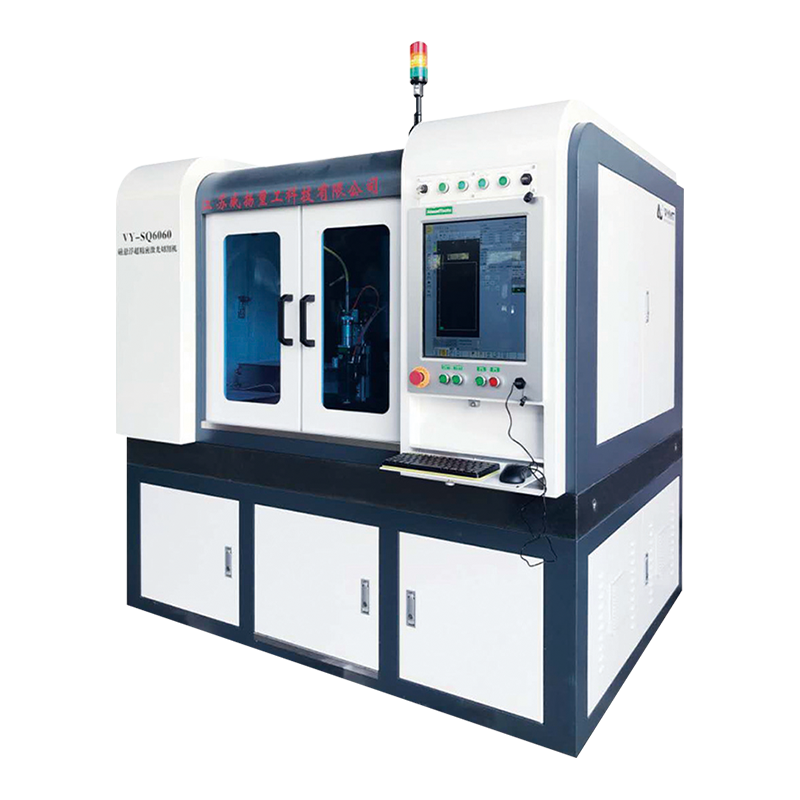

The high precision and consistency of CNC laser cutting machines is one of their most significant advantages. Laser cutting machines use a highly concentrated beam to cut through materials with extremely high energy density. This method enables extremely fine cutting edges, even down to the micron level. This is critical in many demanding manufacturing areas. For example, in the aerospace industry, the accuracy of parts is directly related to the safety and performance of the aircraft. The high precision of CNC laser cutting machines can ensure that every component meets strict design standards, thus improving the reliability of the entire machine.

High-precision cutting also reduces material waste. Traditional cutting methods, such as mechanical cutting or water cutting, often result in material loss and rough edges. Laser cutting can minimize material waste by precisely controlling the position and energy of the beam, and the cutting edge is smooth without the need for secondary processing. This not only improves material utilization, but also reduces processing steps and time, thereby reducing production costs.

Versatility and flexibility

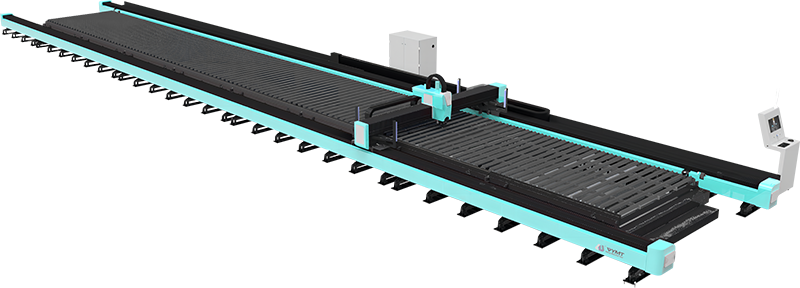

The versatility and flexibility of CNC laser cutting machines is one of the reasons why they are widely used in so many industries. Laser cutting technology is suitable for a variety of materials, including metals (such as steel, aluminum, copper), non-metals (such as plastics, wood, glass) and composite materials. Whether it is a sheet of metal as thin as paper or a steel plate several centimeters thick, the laser cutting machine can handle it easily. This versatility makes laser cutting machines useful in different production environments.

The flexibility of CNC laser cutting machines is reflected in their ability to quickly switch between different cutting tasks. Through programming, operators can preset multiple cutting plans and quickly switch between different materials and shapes. This is especially important for industries that require customized production. For example, in the home decoration industry, customers often need different furniture or decorations customized according to their personal needs. The CNC laser cutting machine can quickly adjust the cutting plan to meet the diverse needs of customers and improve production efficiency.

efficiency and speed

The efficiency and speed of CNC laser cutting machines are their significant advantages. Compared with traditional cutting methods, laser cutting machines can process faster. For example, for thicker metal materials, traditional cutting methods may take hours or even days to complete, while laser cutting machines can complete the cutting in just a few minutes. This efficient cutting speed not only shortens the production cycle, but also improves the overall efficiency of the production line.

CNC laser cutting machines have a high degree of automation and can operate 24 hours a day. This reduces reliance on manual operations and lowers labor costs. Automated operations also reduce the possibility of human error and improve the consistency and stability of production. For large-scale production companies, the efficient operation of laser cutting machines can significantly increase output and meet market demand.

2. What are the main application areas of CNC laser cutting machines?

Manufacturing industry

In the manufacturing industry, CNC laser cutting machines are widely used. Its high precision and high efficiency make it an ideal choice for the production of metal parts. Taking the automotive manufacturing industry as an example, there are many types of automotive parts, including body, chassis, engine parts, etc. These parts not only require precise dimensions, but also good strength and durability. CNC laser cutting machines can meet these requirements and produce high-quality parts that meet design standards through precise cutting and engraving.

In addition to the automotive manufacturing industry, the electronics manufacturing industry is also an important application area for CNC laser cutting machines. Modern electronic products have extremely high requirements for the size and shape of parts, such as mobile phones, computers, and home appliances. Laser cutting technology can cut extremely fine lines and holes to ensure the accurate installation and function realization of electronic components. In addition, laser cutting machines can also perform precise marking and engraving to add unique logos and decorations to products.

Construction and decoration

In the construction and decoration industries, CNC laser cutting machines also play an important role. In the construction industry, laser cutting machines are used to manufacture various metal structural parts and decorative parts, such as stair handrails, curtain wall systems, guardrails, etc. These parts need to have not only good mechanical properties, but also beautiful appearance. Laser cutting machines can produce high-quality parts that meet design requirements through precise cutting and polishing, and improve the overall beauty and safety of buildings.

In the decoration industry, laser cutting machines are used to make various exquisite decorations and furniture. Such as metal carvings, wooden furniture, glass ornaments, etc. Laser cutting technology can achieve complex patterns and shapes to meet the needs of personalization and customization. Through laser cutting, the edges of decorations and furniture are smooth, and the details are finely processed, which improves the grade and quality of the products.

Advertising and logos

In the advertising and logos industry, CNC laser cutting machines are widely used to make various billboards, signs, display stands, etc. The design of billboards and signs often requires delicate patterns and texts, and laser cutting technology can achieve high-precision cutting to ensure that every detail is perfectly presented. In addition, laser cutting machines can also cut a variety of materials, such as metal, acrylic, wood, etc., to meet the needs of different advertising designs.

The production of display stands also benefits from laser cutting technology. Through precise cutting and assembly, the display stand is not only structurally stable, but also has good visual effects, which can attract more customer attention. The efficient production capacity of laser cutting machines can also shorten production time and respond quickly to market demand.

Medical equipment

In the medical field, the application of CNC laser cutting machines is also indispensable. The production of medical devices and tools requires extremely high precision and reliability, such as surgical instruments, implants, diagnostic equipment, etc. Laser cutting technology can achieve precise cutting and grinding to ensure that every medical device meets strict quality standards. Through laser cutting, the edges of medical devices are smooth and free of sharp burrs, reducing the pain and risk of infection for patients.

Laser cutting machines can also be used to manufacture complex medical equipment components, such as CT scanners, MRI equipment, etc. These devices require precise parts to ensure their normal operation and accurate diagnosis. Laser cutting technology can achieve high-precision cutting, produce parts that meet design requirements, and ensure the stability and reliability of medical equipment.

3. What is the future development trend of CNC laser cutting machines?

Intelligence and automation

In the future, CNC laser cutting machines will be increasingly integrated with intelligent and automated technologies. Through the Internet of Things (IoT) and artificial intelligence (AI) technologies, laser cutting machines can achieve remote monitoring, fault diagnosis and automatic optimization. For example, through the Internet of Things technology, laser cutting machines can be interconnected with other equipment and systems to form an intelligent manufacturing network. In this way, operators can understand the operating status of the equipment in real time through the remote monitoring system, discover and solve problems in time, and improve the reliability and production efficiency of the equipment.

The introduction of artificial intelligence technology will make laser cutting machines more intelligent. Through machine learning algorithms, laser cutting machines can automatically adjust cutting parameters and optimize cutting effects based on historical data and current status. AI technology can also help laser cutting machines perform self-diagnosis and fault prediction, discover potential problems in advance, and reduce downtime and maintenance costs. The combination of intelligence and automation will make laser cutting machines more efficient and flexible in future production processes.

Green and environmental protection

With the continuous improvement of environmental protection requirements, future CNC laser cutting machines will pay more attention to energy conservation and emission reduction. Laser cutting technology itself is efficient and clean, and compared with traditional cutting methods, laser cutting produces less waste and pollutants. However, in order to further reduce the impact on the environment, future laser cutting machines will adopt more environmentally friendly designs and technologies. For example, use energy-efficient lasers to reduce energy consumption; use advanced exhaust gas treatment systems to reduce the emission of harmful gases; optimize cutting processes to reduce material waste and waste generation.

The concept of green environmental protection will also run through the entire life cycle of the laser cutting machine. From design, manufacturing to use and scrapping, environmental protection factors will be considered in every link. In the manufacturing process, environmentally friendly materials and processes are used; in the use process, intelligent management and maintenance are used to extend the life of the equipment and reduce resource consumption; in the scrapping process, waste generation is reduced through recycling and reuse. These measures will help laser cutting machines achieve sustainable development and reduce the impact on the environment.

Multifunctional integration

The future CNC laser cutting machine will gradually develop in the direction of multifunctional integration. The needs of modern manufacturing are becoming increasingly diversified, and single-function equipment is difficult to meet complex production requirements. Therefore, multifunctional integration will become one of the development trends of laser cutting machines. By integrating multiple processing technologies, such as cutting, welding, marking, etc., laser cutting machines will be able to complete multiple processes and improve the flexibility and production efficiency of the production line.

Another advantage of multifunctional integration is to reduce equipment investment and floor space. A multifunctional integrated laser cutting machine can replace multiple single-function equipment, reducing the company's equipment investment and maintenance costs. At the same time, multifunctional integrated equipment occupies a smaller area, which is conducive to optimizing production layout and improving production efficiency. For example, in the automobile manufacturing process, the laser cutting machine can not only complete the cutting of body parts, but also weld and mark. One device can complete multiple processes, improving the automation level and overall efficiency of the production line.

Application of new materials

With the continuous emergence of new materials, CNC laser cutting machines will continue to adapt to and apply these new materials. Traditional materials such as steel and aluminum have been widely used in the field of laser cutting, and in the future, lightweight and high-strength new materials will gradually become the main objects of laser cutting technology. For example, carbon fiber composite materials, titanium alloys, high-strength plastics, etc., these new materials have excellent performance and are widely used in high-tech fields such as aerospace, automobiles, and electronics.

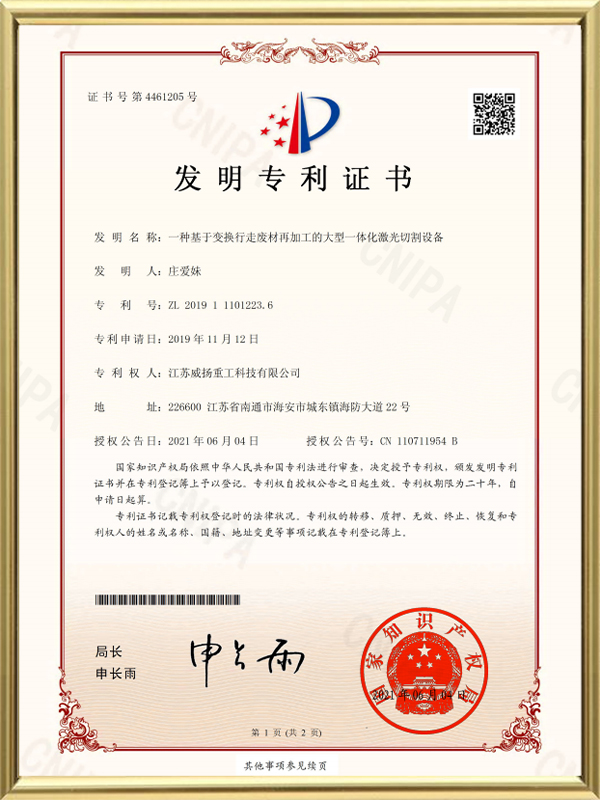

In order to meet the cutting needs of these new materials, future laser cutting machines will adopt more advanced laser technology and processes. For example, ultrafast laser technology can achieve high-precision cutting of ultra-thin materials; multi-beam laser technology can process multiple layers of materials at the same time to improve cutting efficiency; variable frequency laser technology can adjust the frequency and power of the laser to meet the cutting requirements of different materials. The application of these technologies will further expand the application areas of laser cutting machines and meet the needs of different industries for new materials.