Seamless pipes play an important role in the field of industrial manufacturing due to their high strength, good corrosion resistance and high dimensional accuracy. The production of seamless pipes involves a series of complex processes that rely heavily on specialized accessories and equipment, which not only help the smooth operation of production, but also improve product quality and efficiency.

At the heart of seamless pipe production is the heating furnace, which is a key accessory for converting solid steel billets into forgeable and formable materials. Heating furnaces are available in various designs, such as step-through or push-in, each tailored to specific production requirements.

In steel mills, large heating furnaces are used to uniformly heat steel billets to temperatures above 1200°C to ensure optimal plasticity for subsequent piercing and rolling operations. The latest advances in furnace technology focus on improving energy efficiency, reducing emissions and optimizing heating curves to minimize material waste. The ability of heating furnaces to heat different grades of steel, including alloy steel, stainless steel and carbon steel, highlights the versatility of heating furnaces in seamless pipe production.

Piercing Machine: After heating, the billet enters the piercing machine where it is transformed into a hollow shell, called a shell or tube nozzle. The piercing machine is equipped with special tools and dies that apply tremendous pressure and force to pierce the billet.

Two- and three-component piercing: Depending on the scale of production and the material, two-component (two-roll) or three-component (three-roll) piercing machines can be used. Three-component piercing allows for better control of the shell size and wall thickness.

Precision Engineering: The precision of the piercing process directly affects the quality of the final pipe. High-precision tools and automatic control systems ensure consistent shell dimensions and minimize defects.

Material Expansion: The piercing process also involves material expansion, where the pierced shell stretches and becomes thinner as it passes through the mill. This expansion needs to be tightly controlled to maintain the desired pipe size.

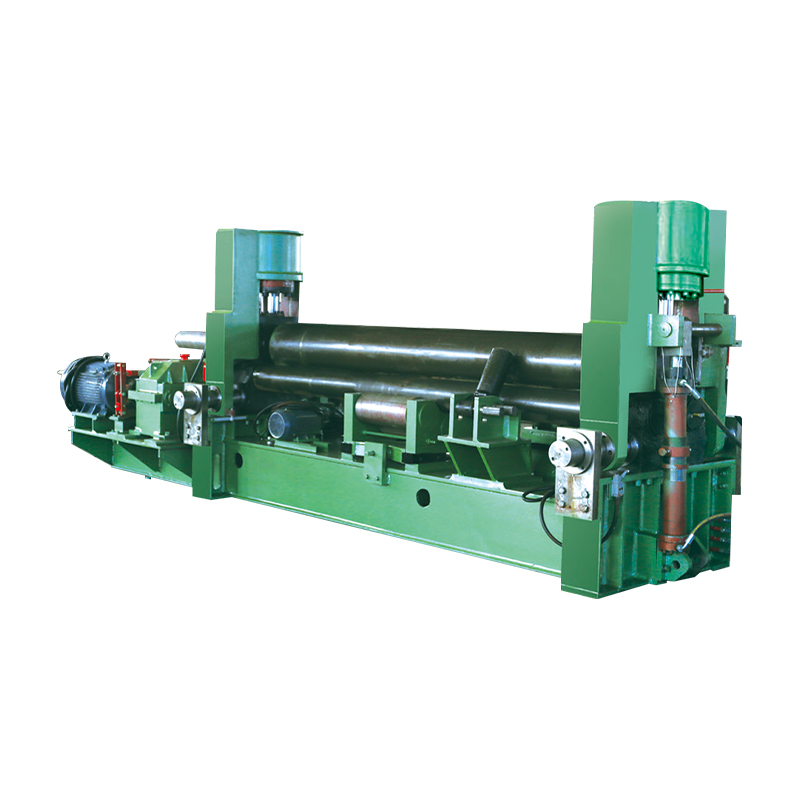

Rolling Mill: After piercing, the tube shell enters a series of rolling mills where it is further deformed to achieve the desired pipe size. Rolling mills are available in various configurations, including mandrel mills, plug mills, and stretch-reducing mills.

Mandrel Mills: These mills use a rotating mandrel inside the tube shell to control its inside diameter and wall thickness. Mandrel mills are particularly suited to producing high-precision pipes with tight tolerances.

Plug Mills: Plug mills utilize a solid plug shaft that passes through the tube shell, reducing its diameter and wall thickness simultaneously. They are often used in conjunction with mandrel mills to perform complex reductions.

Stretch Reducing Mills: For larger diameter pipes, stretch reducing mills employ a series of rolls that gradually reduce the cross-sectional area of the pipe while stretching it. This process improves the mechanical properties and surface finish of the pipe.

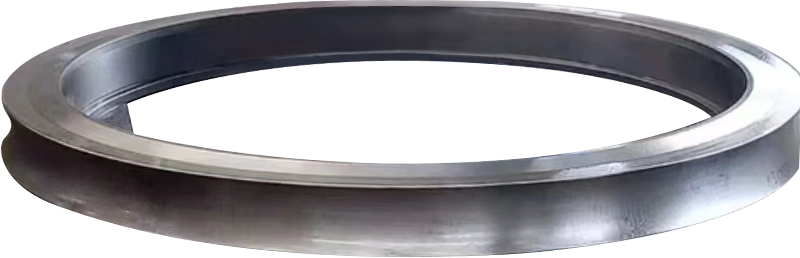

Sizing and Straightening Equipment: After seamless pipe is rolled, it is often necessary to sizing and straightening to meet tight dimensional and straightness specifications.

Sizing Mills: Sizing mills are used to fine-tune the outside diameter and wall thickness of a pipe to ensure compliance with international standards.

Straightening Mills: Straightening mills apply controlled forces to the surface of the pipe, correcting any deviations from a perfectly straight line. This is critical for pipes used in critical applications such as oil and gas delivery.

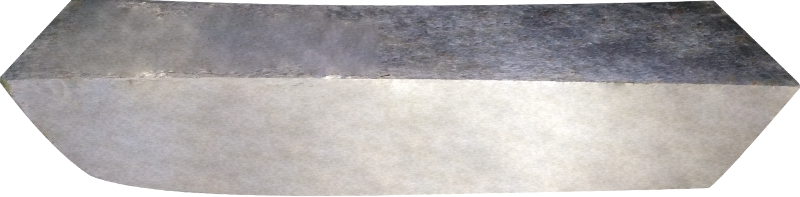

Cutting and trimming tools: After the pipe is sized and straightened, specialized cutting and trimming tools are used to cut it to precise lengths.

Cold saws and flying shears: Cold saws provide clean, burr-free cuts for small and medium diameter pipes. Flying shears are high-speed cutting devices suitable for large production lines, capable of cutting pipe at high speeds without stopping the line.

Facing and chamfering: After cutting, the pipe may be faced and chamfered in preparation for welding or other joining processes.