1.What are the advantages of CNC rolling machine?

Efficient production

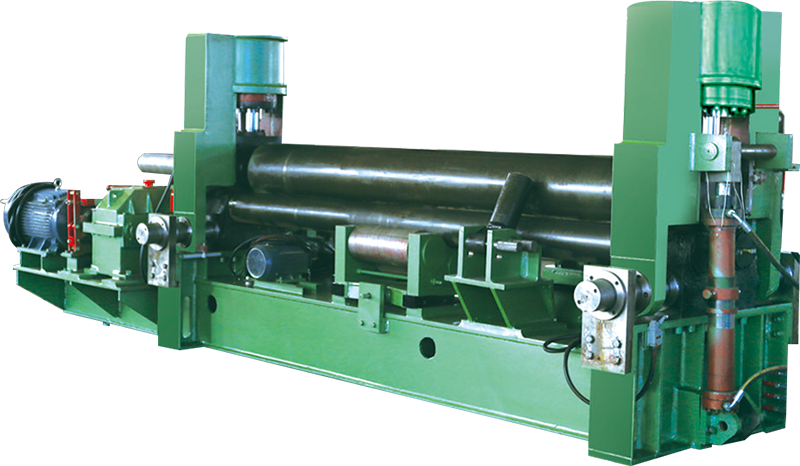

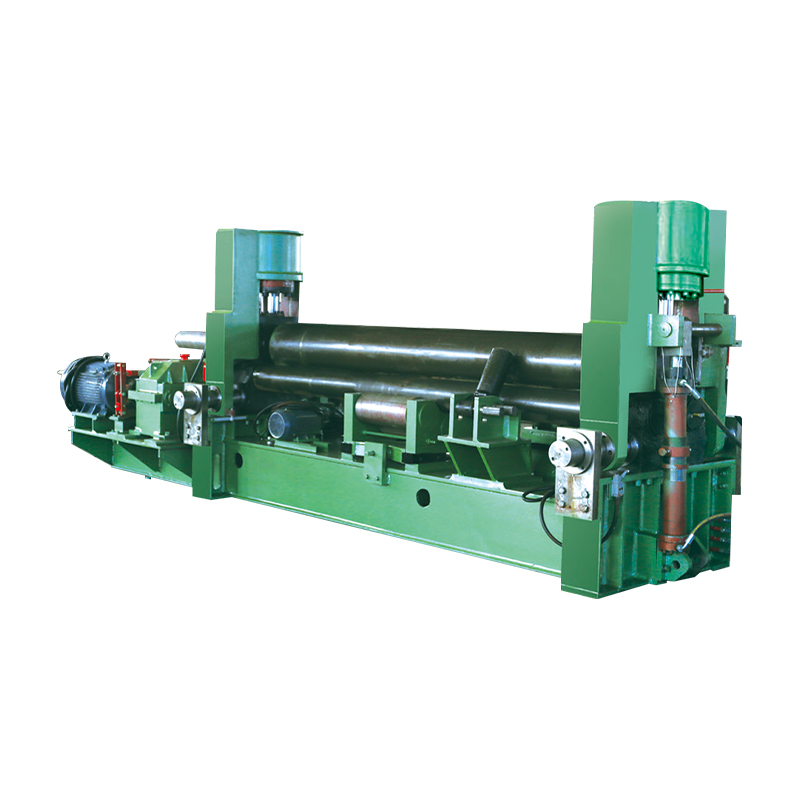

The efficient production capacity of CNC rolling machines is one of its significant advantages. The traditional manual rolling process requires a lot of time and labor, but the CNC rolling machine realizes automated production through computer control, greatly improving production efficiency. For example, traditional manual rolling may require multiple workers to collaborate to complete a complex part, while a CNC rolling machine only requires one operator to set up the program, and the machine can automatically complete the entire rolling process. This automated production not only saves labor, but also reduces human errors and improves product consistency and quality.

The quick mold change function of the CNC rolling machine also greatly shortens production preparation time. By presetting a variety of molds and parameters, operators can quickly switch between different rolling tasks to meet the production needs of different products. This is particularly important for companies that produce multiple varieties and small batches, so they can quickly respond to market changes and improve market competitiveness.

High accuracy and consistency

CNC rolling machines utilize advanced computer numerical control technology to achieve high-precision and high-consistency rolling processing. By precisely controlling the position and pressure of the rolling tool, CNC rolling machines are able to form complex geometries and subtle structures on materials. For example, in the automotive manufacturing industry, body parts require precise shapes and sizes to ensure assembly accuracy and vehicle safety performance. The high-precision machining of CNC rolling machines can meet these strict requirements and produce high-quality parts.

Consistency is also an important advantage of CNC rolling machines. Because the rolling process is controlled by computer, the processing parameters of each part can be accurately replicated, ensuring that every product is of the same quality. This consistency is particularly important in mass production, which can significantly reduce the defective rate and improve production efficiency and product market competitiveness.

Versatility and flexibility

The versatility and flexibility of CNC rolling machines enable them to adapt to a variety of different production needs. Modern manufacturing has a wide range of products, and production processes are constantly changing and upgrading. CNC rolling machines can quickly adapt to the processing needs of different materials and products by replacing different molds and tools. For example, in the pipe manufacturing industry, CNC rolling machines can process pipes of various diameters and wall thicknesses to meet the needs of different pipe systems.

The flexibility of CNC rolling machines is also reflected in their programming capabilities. By writing different processing programs, operators can implement various complex rolling processes, such as spiral rolling, tapered rolling, etc. This flexibility makes the CNC rolling machine not only suitable for the mass production of standardized products, but also capable of producing personalized and customized products to meet the diverse requirements of customers.

2. What are the main application areas of CNC rolling machines?

Automotive Manufacturing

In the automotive manufacturing industry, CNC rolling machines are widely used in the production of body parts, chassis structures and exhaust systems. Body parts require complex geometries and high-strength materials, and traditional manual machining methods are difficult to meet these requirements. The CNC rolling machine can produce body parts that meet the design requirements through high-precision and high-efficiency rolling processing, improving the overall performance and safety of the vehicle.

The chassis structure is one of the key components of the automobile and requires good load-bearing capacity and impact resistance. CNC rolling machines can process high-strength chassis structures to ensure vehicle stability and reliability during driving. In addition, the pipes of the exhaust system require precise bending and shaping to ensure smooth exhaust and the vehicle's environmental performance. The high-precision machining of CNC rolling machines is able to meet these requirements and produce high-quality exhaust system components.

Architecture and Engineering

In the field of construction and engineering, CNC rolling machines also play an important role. Building structural members such as steel beams and columns need to have high strength and precise dimensions to ensure the stability and safety of the building. The CNC rolling machine can produce building structural parts that meet the design requirements through precise rolling processing, improving the overall performance of the building.

CNC rolling machines are also widely used in bridge construction, tunnel engineering and the production of pipe systems. In bridge construction, the bridge's main beams and supporting structures require precise processing and high-strength materials. The CNC rolling machine can process bridge parts that meet the requirements, ensuring the safety and durability of the bridge. In tunnel engineering, the supporting structure and lining of the tunnel require precise dimensions and good strength, and CNC rolling machines are also capable of these tasks. The production of pipeline systems is also inseparable from CNC rolling machines. Through precise rolling processing, pipes of various diameters and wall thicknesses are produced to meet the needs of different pipeline systems.

Ships and Aerospace

In the fields of shipbuilding and aerospace, CNC rolling machines are also indispensable equipment. During the ship manufacturing process, the hull structure and deck components require precise rolling processing to ensure the safety and stability of the ship. The CNC rolling machine can produce hull parts that meet the requirements through high-precision rolling processing, improving the overall performance and service life of the ship.

The aerospace field has stricter requirements on precision and quality of components. Aircraft fuselage structures, wings and engine components require extremely high precision and consistency. CNC rolling machines can produce high-quality aviation parts through precise control and processing, ensuring the safety and reliability of aircraft. In addition, the structural parts and components of spacecraft also require high-precision processing. CNC rolling machines are capable of these tasks and provide reliable support for the manufacturing of spacecraft.

3. What is the future development trend of CNC rolling machines?

Intelligence and automation

In the future, CNC rolling machines will develop in the direction of intelligence and automation. Through the Internet of Things (IoT) and artificial intelligence (AI) technology, CNC rolling machines can achieve remote monitoring, automatic adjustment and fault diagnosis. For example, through the Internet of Things technology, operators can monitor the operating status of the rolling machine in real time, discover and solve problems in time, and improve the reliability and production efficiency of the equipment. The introduction of artificial intelligence technology will make CNC rolling machines more intelligent, and through machine learning algorithms, automatically optimize processing parameters, improve processing accuracy and efficiency.

The application of automation technology will further improve the production efficiency of CNC rolling machines. Through functions such as automatic loading and unloading, automatic mold changing and automatic cleaning, CNC rolling machines can achieve unmanned production, reduce manual intervention and reduce labor costs. This development trend of intelligence and automation will make CNC rolling machines more efficient and flexible in the future production process, meeting the diversified needs of modern manufacturing.

Environmental protection and energy saving

With the continuous improvement of environmental protection requirements, future CNC rolling machines will pay more attention to environmental protection and energy saving. Traditional rolling processes may generate a large amount of waste and pollutants, while CNC rolling machines can reduce the generation of waste and pollutants by precisely controlling and optimizing processes. In addition, CNC rolling machines will also adopt more environmentally friendly materials and processes to reduce the impact on the environment.

Energy saving is also an important direction for the development of CNC rolling machines in the future. By adopting efficient and energy-saving motors and control systems, CNC rolling machines can reduce energy consumption and improve energy utilization efficiency. In addition, by optimizing processing technology and reducing processing time, CNC rolling machines can further reduce energy consumption and achieve green manufacturing.

Multifunctional integration

The future CNC rolling machines will gradually develop in the direction of multifunctional integration. By integrating multiple processing technologies, such as cutting, welding, marking, etc., CNC rolling machines will be able to complete multiple processes and improve the flexibility and production efficiency of the production line. Multifunctional integration can not only meet the processing needs of complex parts, but also significantly reduce equipment investment and floor space, optimize production layout, and improve production efficiency.

In modern manufacturing, different production tasks often require different processing techniques and equipment. By integrating multiple processes into one CNC rolling machine, companies can significantly reduce equipment investment and maintenance costs. For example, in the process of automobile manufacturing, the processing of body parts requires not only rolling, but also cutting, welding and marking. Multifunctional integrated CNC rolling machines can achieve seamless switching of these processes by replacing different molds and tools, improving production efficiency and product quality.

Multifunctional integrated CNC rolling machines can also realize automatic control of complex processes through intelligent control systems. For example, by programming different processing parameters and process flows, CNC rolling machines can automatically complete multiple processes, reduce manual intervention and operating errors, and improve processing accuracy and consistency. In addition, multifunctional integration can also optimize processing parameters and processes through real-time monitoring and feedback, and improve production efficiency and equipment utilization.

Application of new materials

As new materials continue to emerge, CNC rolling machines will continue to adapt to and apply these new materials. Traditional materials such as steel and aluminum have been widely used in the field of rolling processing, and in the future, lightweight and high-strength new materials will gradually become the main objects of rolling technology. For example, carbon fiber composite materials, titanium alloys, high-strength plastics, etc., these new materials have excellent performance and are widely used in high-tech fields such as aerospace, automobiles, and electronics.

In order to meet the processing needs of these new materials, future CNC rolling machines will adopt more advanced technologies and processes. For example, ultrafast laser technology can achieve high-precision processing of ultra-thin materials; multi-beam laser technology can process multiple layers of materials at the same time to improve processing efficiency; variable frequency laser technology can adjust the frequency and power of the laser to meet the processing requirements of different materials. The application of these technologies will further expand the application field of CNC rolling machines and meet the needs of different industries for new materials.