What are the design features of CNC hydraulic shearing machine?

CNC hydraulic shearing machine is a kind of high-precision and high-efficiency metal processing equipment widely used in the metal processing industry. It adopts advanced CNC technology and is equipped with high-performance CNC system and servo drive system to achieve precise cutting control and high-speed movement, thereby realizing high-precision and high-efficiency metal cutting processing. The CNC system accurately controls the movement trajectory and cutting speed of the tool through pre-programmed cutting parameters and paths, realizes precise cutting operation and improves production efficiency.

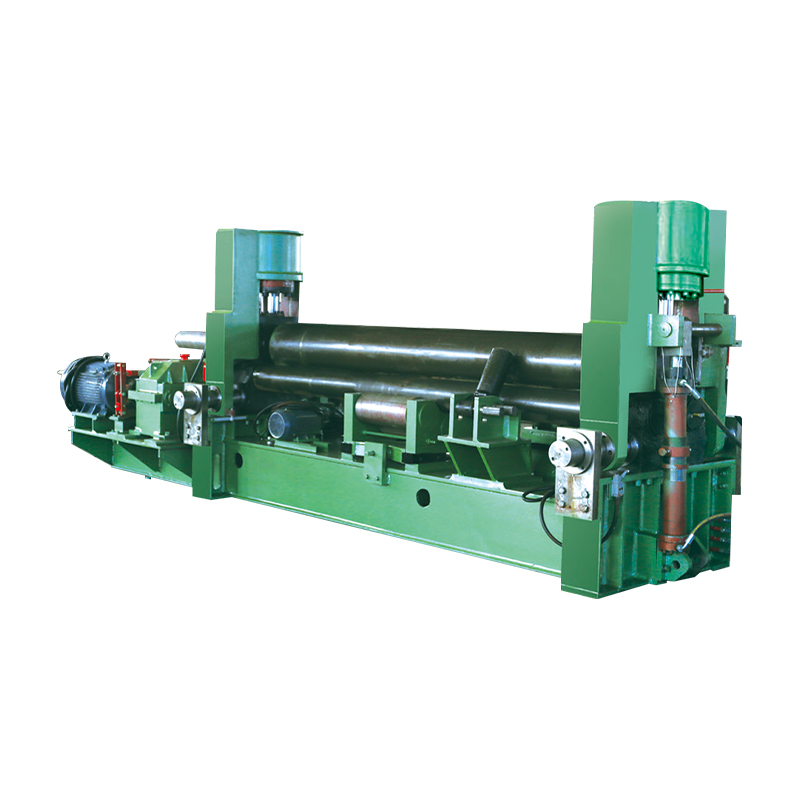

CNC hydraulic shearing machine has a sturdy and stable structural design. It is made of high-quality steel and is precision machined and heat treated to ensure that the equipment has good rigidity and stability. The tool holder, workbench and hydraulic system of the equipment are precisely designed and optimized, so that the equipment can maintain stable operation during high-speed cutting, ensuring cutting accuracy and cutting quality.

In addition, CNC hydraulic shearing machine has a multifunctional design, which can realize a variety of cutting processes and cutting forms, such as straight cutting, curve cutting, multi-segment cutting, etc. The equipment is equipped with a variety of tools and fixtures to adapt to metal materials of different shapes and thicknesses to meet different processing needs. The equipment also has the functions of automatic tool change and automatic adjustment of tool gap, which improves production efficiency and operation convenience.

In terms of humanization and intelligence, the CNC hydraulic shearing machine is well designed, equipped with a touch screen interface and an intelligent control system, and is easy to operate. The operator sets parameters, adjusts tools and diagnoses faults through the touch screen interface to achieve intelligent operation control. The equipment is also equipped with an automated material level control and back gauge system to achieve continuous production operations and improve production efficiency.

Safety and environmental protection are important considerations in the design of CNC hydraulic shearing machines. The equipment is equipped with multiple safety protection devices and environmental protection facilities, such as safety fences, emergency stop buttons, overload protection, safety gratings, etc., to ensure the safety of operators and equipment. At the same time, the equipment has an energy-saving and environmentally friendly design, using advanced hydraulic systems and energy-saving motors to reduce energy consumption and reduce environmental pollution.

What are the common fault problems of CNC hydraulic shearing machines?

As a high-precision and high-efficiency metal processing equipment, CNC hydraulic shearing machines may have various fault problems during long-term operation, affecting the normal operation and production efficiency of the equipment.

Hydraulic system failure is a key problem of CNC hydraulic shearing machine. Common failures include hydraulic oil leakage, high hydraulic oil temperature, hydraulic cylinder jamming, etc. These problems may lead to unstable equipment pressure and reduced cutting quality. Solutions include checking whether the seals and pipelines of the hydraulic system are leaking, replacing damaged parts; cleaning the hydraulic system and replacing new hydraulic oil; checking whether the hydraulic cylinder and valve are jammed, and repairing or replacing them.

Electrical system failure is another common problem, including motor failure, sensor failure, control system failure, etc. These problems may cause the equipment to fail to start normally and cannot be accurately positioned. Solutions include checking whether the connection between the motor and sensor is good and replacing damaged parts; checking the program and parameter settings of the control system, and re-debugging or updating the program.

Tool and fixture failure is also one of the common failures, including tool wear and fixture failure. These problems may lead to reduced cutting quality and reduced cutting accuracy. Solutions include regularly checking the wear of the tool and replacing the severely worn tool in time; adjusting the clamping force of the fixture to ensure that the workpiece is firmly clamped.

Mechanical component failures also need to be focused on, including loosening and wear of components such as tool holders, workbenches, and guide rails. These problems may cause unstable operation of the equipment and reduced cutting accuracy. Solutions include regularly checking whether the fasteners of mechanical parts are loose, tightening or replacing damaged parts; lubricating mechanical parts to reduce friction and extend service life.

Finally, safety system failures are also issues that need to be paid attention to, including failure of components such as safety fences, emergency stop buttons, safety gratings, and alarm system failures. These problems may cause safety hazards to the equipment. Solutions include regularly checking whether the safety system functions normally, replacing damaged parts; resetting the parameters of the safety system to ensure safe operation of the equipment.

How does the CNC Sweeper Truck maintain consistent suction and sweeping efficiency in high-dust environments?

1. High-Efficiency Brush and Suction System The CNC Sweeper Truck is equipped with precision-engineered rotating brushes and powerful suction mechanisms designed to capture both fine dust and larger d...

READ MORE