-

26 Jan’ 2026

How does the CNC Sweeper Truck maintain consistent suction and sweeping efficiency in high-dust environments?

1. High-Efficiency Brush and Suction System The CNC Sweeper Truck is equipped with precision-engineered rotating brushes and powerful suction mechanisms designed to capture both fine dust and larger d...

-

19 Jan’ 2026

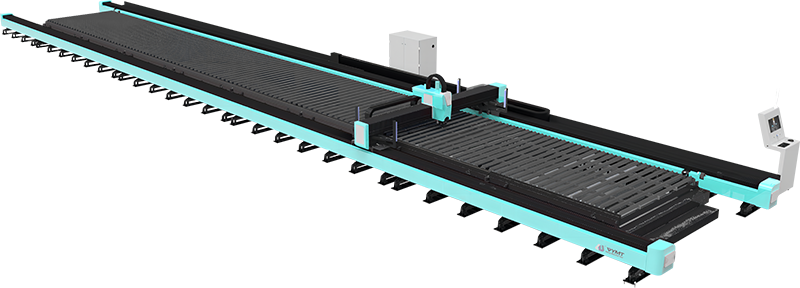

How does the CNC Laser Cutter manage heat-affected zones to minimize material warping or discoloration during cutting?

Understanding Heat-Affected Zones (HAZ)The heat-affected zone (HAZ) refers to the area adjacent to the laser cut where the material experiences thermal changes that do not completely melt the material...

-

12 Jan’ 2026

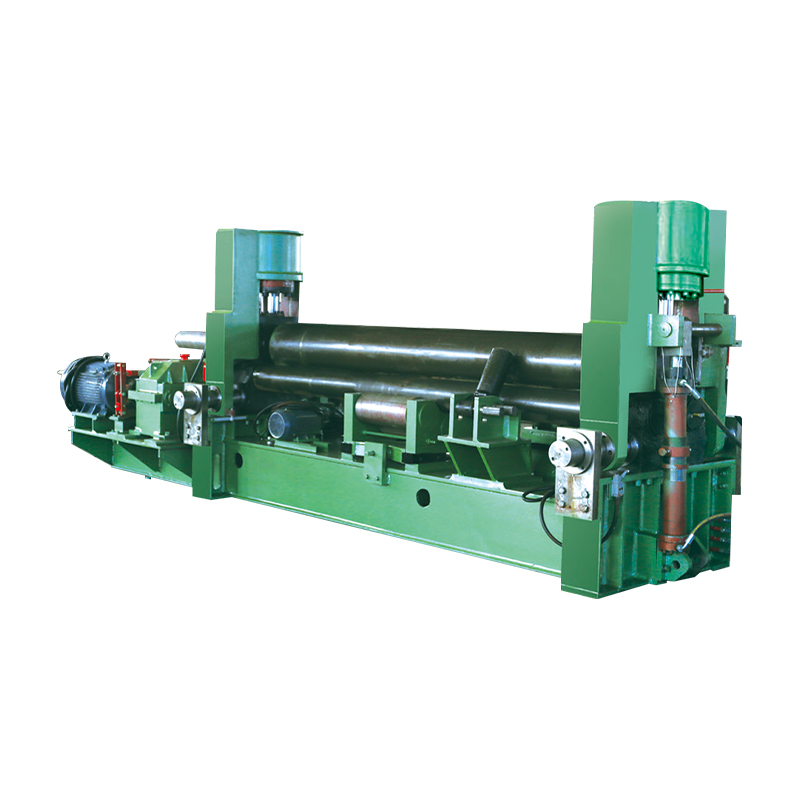

How does the Three-Roller Plate Bending Machine maintain consistent bending quality across varying plate lengths?

Roller Alignment and Adjustable Support The Three-Roller Plate Bending Machine maintains consistent bending quality across plates of varying lengths primarily through precise roller alignment and adju...

-

05 Jan’ 2026

How does the Three-Roller Plate Bending Machine ensure precise bending accuracy and minimize material deformation?

Roll Positioning and Alignment The Three-Roller Plate Bending Machine ensures precise bending accuracy through carefully engineered roll positioning and alignment. Its triangular roller configuration ...

-

29 Dec’ 2025

How does the Ground Rail Laser Cutting Machine handle thermal distortion and maintain dimensional accuracy during prolonged cutting cycles?

The Ground Rail Laser Cutting Machine is engineered with a strong emphasis on thermal stability to ensure consistent dimensional accuracy during long, continuous cutting operations. One of the most cr...

-

23 Dec’ 2025

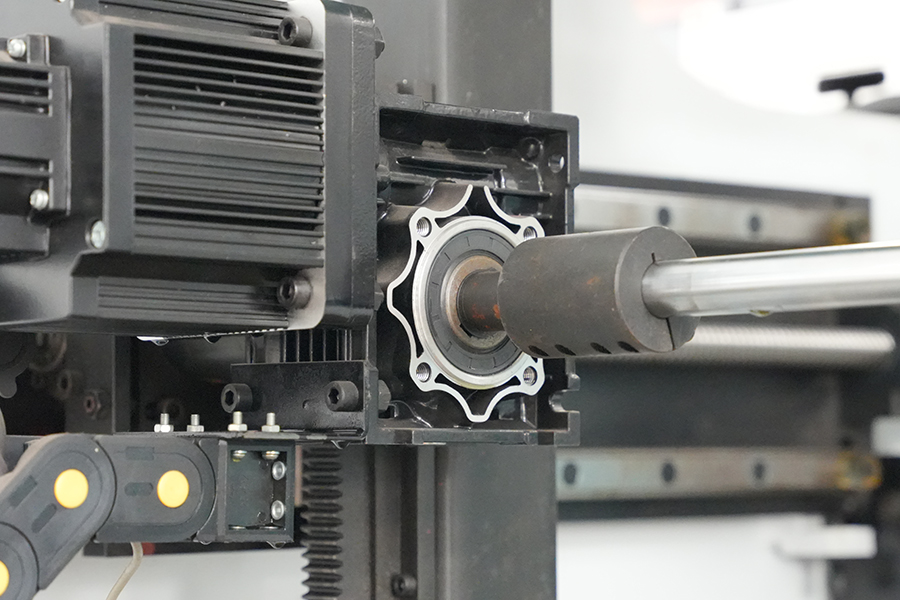

How does a CNC Rolling Machine manage thermal expansion and mechanical stress during high-precision rolling tasks?

Thermal Expansion Management CNC Rolling Machines are engineered to handle the thermal expansion that naturally occurs during high-precision rolling operations. Friction between the rollers and the wo...

-

16 Dec’ 2025

How does the CNC Sweeper Truck ensure efficient debris collection across various surfaces, such as asphalt, gravel, and concrete?

Adjustable Sweeping Mechanism for Versatility The CNC Sweeper Truck is designed with adjustable brushes that offer flexibility for cleaning a wide range of surfaces. For smoother surfaces like asphalt...

-

09 Dec’ 2025

How does the Handheld Snow Blower manage ice or compacted snow that is harder than freshly fallen snow?

Auger and Impeller DesignThe core mechanism for handling ice or compacted snow in Handheld Snow Blower lies in the design and material selection of the auger and impeller system. The auger must be c...

-

02 Dec’ 2025

How does the CNC Rolling Machine handle material distortion and springback during the rolling process, and what measures are in place to compensate for these effects?

Understanding Material Distortion and Springback Material distortion and springback are two critical challenges in the rolling process that can affect the quality and accuracy of the final product. Ma...

-

24 Nov’ 2025

How does the hydraulic system in a CNC Hydraulic Shearing Machine contribute to its cutting force and efficiency compared to other types of shear machines?

1. Consistent Cutting Force The hydraulic system in CNC Hydraulic Shearing Machine is integral to its ability to deliver a consistent cutting force, which is essential for achieving precision and repe...

-

17 Nov’ 2025

How does the CNC Rolling Machine ensure consistent quality and uniform curvature in batch production?

Computer Numerical Control (CNC) Precision: The cornerstone of consistent output in CNC Rolling Machines is the computer numerical control system, which governs all aspects of roller motion, speed, ...

-

10 Nov’ 2025

How does the CNC Rolling Machine maintain uniform curvature and surface finish across large or complex workpieces?

Precision Roll Alignment – The rollers in CNC Rolling Machine are manufactured with micron-level tolerances and installed with extreme precision to ensure parallelism and concentricity along the ent...